The 30-Second Trick For Manufacturing Industriess

Wiki Article

Some Known Details About Manufacturing Industries

Table of ContentsDie Casting for DummiesUnknown Facts About Hon Hai PrecisionThe Facts About Mfg UncoveredThe Buzz on Lean ProductionWhat Does Lean Manufacturing Mean?

After that, the mould shuts as well as the procedure repeats. Pre-moulded or machined elements can be placed right into the cavity while the mould is open, enabling the product infused in the following cycle to form and solidify around them. This procedure is called Insert moulding and also allows single parts to have numerous products.

The plastic injection moulding industry has actually progressed throughout the years from creating combs and switches to producing a vast selection of products for several markets including auto, medical, aerospace, consumer items, toys, pipes, packaging, and construction.: 12 Instances of polymers finest matched for the process [modify] Many polymers, in some cases described as resins, may be made use of, including all thermoplastics, some thermosets, and some elastomers.

Available products consist of alloys or blends of formerly developed materials, so item developers can choose the material with the finest set of residential properties from a vast selection. Major standards for option of a material are the strength and feature required for the final part, as well as the expense, but additionally each product has different parameters for moulding that have to be taken right into account.: 6 Various other considerations when choosing an injection moulding product consist of flexural modulus of flexibility, or the level to which a product can be bent without damages, as well as heat deflection as well as water absorption.

Oem - Truths

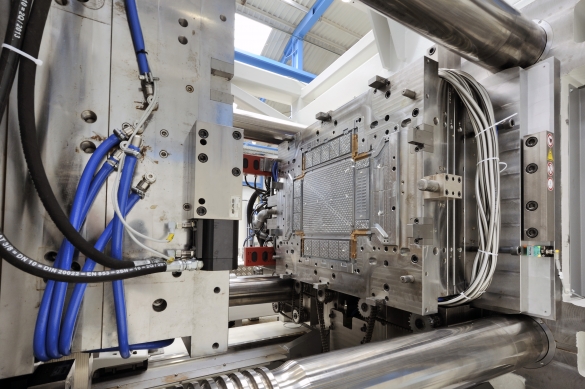

Applications include clasps for anchoring and also disconnecting outdoor-equipment webbing. Shot moulding machines are composed of a material hopper, a shot ram or screw-type plunger, and also a heating unit.: 240 Likewise known as platens, they hold the moulds in which the elements are formed. Presses are rated by tonnage, which expresses the quantity of securing force that the machine can put in.

Mould or pass away are the typical terms utilized to describe the device utilized to generate plastic components in moulding. Considering that moulds have been expensive to make, they were generally only made use of in automation where countless parts were being generated. Normal moulds are constructed from set steel, pre-hardened steel, aluminium, and/or beryllium-copper alloy.: 176 The option of material to build a mould from is largely one of economics; in basic, steel moulds cost even more to build, but their longer life-span offsets the higher initial expense over a greater number of parts made before using out.

The Best Guide To Plastic Manufacturing

Shot moulding die with side draws "A" side of die for 25% glass-filled acetal with 2 side pulls. "B" side of die with side pull actuators. Standard two plates tooling core and also cavity are inserts in a mould base "household mould" of 5 various parts The mould consists of two primary elements, the shot mould (A plate) as well as the ejector mould (B plate).Plastic resin gets in the mould with a or gate in the shot mould; the sprue bushing is to seal securely versus the nozzle of the injection barrel of the moulding machine and also to enable molten plastic to flow from the barrel right into the mould, likewise called the cavity.: 141 The sprue bushing routes the liquified plastic to the cavity pictures through networks that are machined into the faces of the An and B plates.

(A) Sprue, (B)&(C)runner and (D)gates in actual injection moulding item for playthings The amount of material required to fill the sprue, jogger as well as cavities of a mould makes up a "shot". Caught air in the mould can escape through air vents that are ground right into the parting line of the mould, or around ejector pins as well as slides that are slightly smaller than the holes maintaining them.

The air can even end up being so pressed that it ignites and also burns the bordering plastic material.: 147 To enable mass produced elimination of the moulded part from the mould, the mould functions must not overhang each other in the instructions that the mould opens, unless parts of the mould are designed to move from in between such overhangs when the mould opens utilizing parts called Lifters.

Die Casting Can Be Fun For Everyone

The coolant soaks up warmth from the mould (which has actually soaked up warm from the warm plastic) as well as keeps the mould at a proper visit the site temperature level to strengthen the plastic at the most efficient rate.: 86 To ease upkeep and also airing vent, cavities as well as cores are split into pieces, called inserts, and sub-assemblies, additionally called inserts, obstructs, or chase blocks.More complex components are formed using extra complicated moulds. These might have areas called slides, that move right into a cavity perpendicular to the draw instructions, to develop looming part attributes. When the mould is opened, the slides are retreated from the plastic part by utilizing fixed "angle pins" on the stationary mould fifty percent. additive manufacturing.

The part is after that ejected and the mould shuts. The closing action of the mould creates the slides to move on along the angle pins.: 268 A mould can create numerous duplicates of the same components in a single "shot". The number of "impressions" in the mould of that component is frequently improperly described as cavitation.

In many cases, numerous tooth cavity tooling moulds a collection of different components in the same device. Some toolmakers call these moulds family moulds, as all the components are relatede. g., plastic model kits.: 114 Some moulds enable formerly molded parts to be returned to enable a brand-new plastic layer to create around the first component.

The Ultimate Guide To Manufacturing

This system can enable production of one-piece tires and wheels. Two-shot or multi-shot moulds are designed to "overmould" within a single moulding cycle and also have to be processed on specialist injection moulding equipments with 2 or even more injection devices. This procedure is really an injection moulding process executed twice as well as as a result has a much smaller margin of error.Then the second product, a different colour, is injection-moulded right into those rooms. Pushbuttons and also site link secrets, for circumstances, made by this procedure have markings that can not diminish, and also continue to be understandable with heavy use.: 174 Mould storage [modify] Suppliers most likely to wonderful lengths to protect custom moulds as a result of their high average expenses.

Report this wiki page